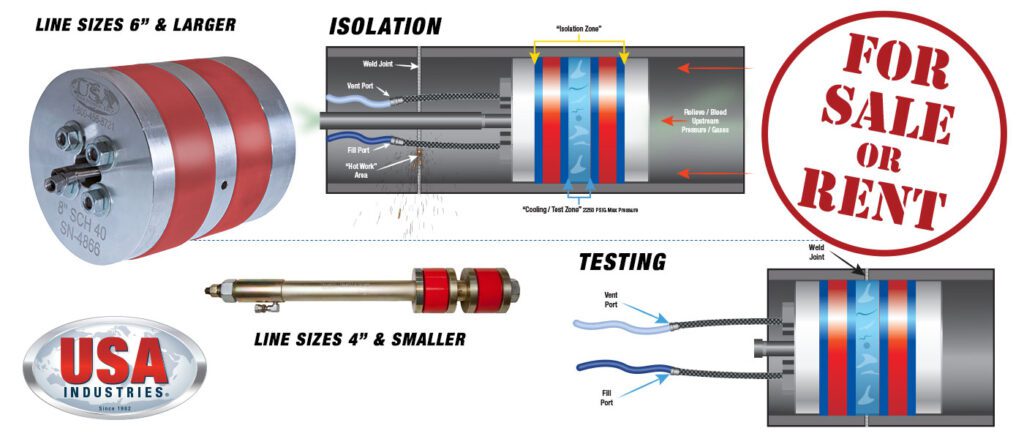

Double Block and Bleed (DBB) Isolation & Testing Plug

Revolutionizing Positive Isolation and Testing of

Pipe Connections - Available for Sale or to Rent

USA Industries' Double Block & Bleed pipe plug is built with two separate sealing areas that allow the user to positively isolate upstream gases from internal piping. As a result of this design, it makes performing modifications, repairs and hot work much safer, quicker and easier. The Double Block & Bleed plug also has a vent between the compression seals that lets the user verify the seals' integrity and pressure test the hydrotest welds by positioning the weld between the two seals.

[bg_collapse view="button-red" color="#fff" icon="arrow" expand_text="Show More" collapse_text="Show Less" inline_css="width: 150px; padding: 10px;" ]

With USA Industries' innovative DBB plug design, the plug is highly portable (aluminum/steel construction) and easy to position. Additionally, the amount of water required is so small that you will be able to conduct your test using a hand pump or hydro pump. This greatly facilitates remote testing in areas throughout your facility.

Additional Advantages of USA Industries' Double Block and Bleed Pipe Plug:

- Plug is portable and easy to position

- Sizes 0.75" to 24" NPS, larger sizes available on request

- Uses less than a gallon of water, reducing waste and treatment expense

- Safety factor reduces non-destructive evaluation (NDE)

- Working pressures to 2,250 PSI (155.2 Bar)

- Monitor isolation zone and upstream pressure, preventing backpressure build-up during tests

HOW IT WORKS

After determining pipe and schedule size:

- Install DBB plug upstream of "hot work" area

- Expand seals by tightening compression nut(s)

- Inject inert gas or water between seals (isolation zone) and pressurize

- Monitor isolation zone and upstream pressure during "hot work"

- After weld cools release pressure and seal, reposition isolation zone over weld area

- Pressurize isolation zone (up to 2,250 psi (155.1Bar))

In addition to making hot work safer, quicker and easier, USA Industries manufactures our isolation and test plugs under a strict quality assurance system. All plugs are certified to ISO 9001 standards.

A SPECIAL WORD OF CAUTION:

Pressure testing is a hazardous operation. Follow safety precautions before, during and after testing is complete. Check that all connections, valves, flanges and other fittings are suitable to test pressure. Verify that the line ID and the plug range match. And most importantly, NEVER stand or pass in front of a test plug or other enclosure while a test is in progress. If a plug discharges during a test, serious injury or death is possible.

[/bg_collapse]

PRODUCT FEATURES:

- Will reduce time and costs to repair and test welds

- Minimizes purge costs and associated waste

- Will leave no damage to the interior pipe walls

- Sizes 0.75" to 24" NPS are standard - larger sizes are available upon request

- For use in low and high-pressure applications

Frequently Asked Questions

Yes! The Double Block & Bleed plug has a vent in between the compression seals that lets you to verify the seals integrity and pressure test / hydrotest welds by positioning the weld between the two seals.

The DBB plug operates in working pressures to 2,250 PSI (155.2 Bar). Use it to monitor isolation zone and upstream pressure, preventing backpressure build-up during tests.

The sealing material is made of urethane.

Our standard urethane seals continuous operating temperature are rated at 180°. We also offer high-temperature seals upon request.

Yes, we have several extended reach sizes available. Just let us know what reach you need.