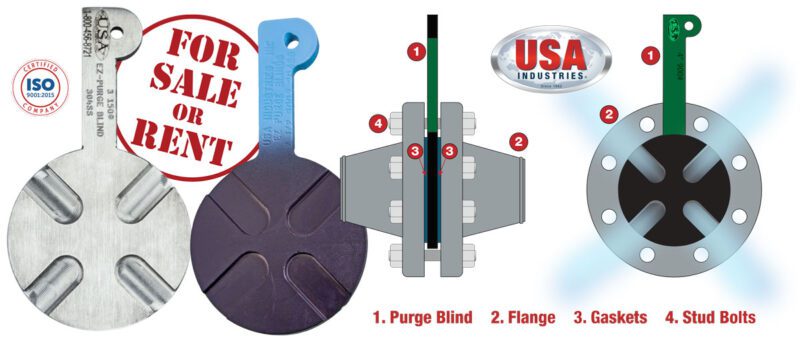

EZ Purge® Slip Blind

Safely Purge While Preventing Equipment Damage from Traditional Methods - Available to Rent or Purchase.

USA Industries' EZ Purge slip blind replaces an unsafe and outdated practice for line purging applications that uses a slip blind and several spacers sandwiched between the blind and the gapped flange. Although this procedure can be used to create a purging area, several problems exist that will lead to unsafe practices and/or damage to the operators equipment.

[bg_collapse view="button-red" color="#fff" icon="arrow" expand_text="Show More" collapse_text="Show Less" inline_css="width: 150px; padding: 10px;" ]

The purge blind creates a "stand off" area at the flange site, that allows for line purging. It seals evenly, resulting in no damage to the flange gasket surfaces associated with using wedges, tubing, or other metals to create space between the blind and flange.

The EZ Purge slip blind is easily identifiable by its uniquely shaped and color coded handle, but we will make it the specification that you request if it is needed. The current standard we use is a 1/2" thick isolation blind with a 1/4" deep channel milled at either 3/4", 1", or 1 1/2" widths depending on the blind size. The ratio of gasket area versus purge area is approximately 50% to allow for proper sealing force distribution.

The blinds come standard in sizes from 1/2" to 96" and flange classes from 150# to 2500#. Unless otherwise specified, the blinds are painted flat black and are stamped with their size & rating for ease of use. Custom configurations are available to suit your specific purge flow requirements. In-stock orders are shipped the same day.

[/bg_collapse]

PRODUCT FEATURES:

- Safer, quicker and easier than traditional purging methods

- Prevents damage to flanges from makeshift spacers

- Unique handle quickly identifies blind as a Purge Blind

NEED PADDLE BLIND STORAGE?

Check Out USA Industries' Patented

EZ Lock Blind Rack®!

Frequently Asked Questions

Our standard thickness is 1/2" with 1/4" milled slots.

We can manufacture hydrotest EZ Purge blinds that will withstand hydrotesting, but our standard blinds are designed for isolation only. Please let us know at the time you're ordering, and we can increase the thickness of the non-purged side to withstand hydrotesting.

Yes, but if you want them much deeper, we will suggest the total thickness of the blind to be increased.

Yes, what you're asking for is our EZ Vent-Purge® blind that combines both the EZ Vent and EZ Purge benefits into one specialty blind.

Carbon steel blind handles are painted to match the standard flange rating colors. All of our slip blinds are indent marked and polished to smooth edges.

We have designed our EZ Purge blind to have an effective purge area of 50% to prevent damage of the gasket surface.

Yes. Our proprietary design allows you use this blind with or without a gasket on the purge side. This will not affect the amount of purge flow.

Yes. We can do both machined 125-250 rms finishes and RTJ male or female surfaces upon request.