Inflatable Pipe Plug / Pipe Balloon Plug

Inflatable Pipe Plugs are the Most Flexible Available with the Greatest Range of Sizes -

Available for Sale or to Rent

USA Industries' Inflatable Pipe Plug, also known as a pipe balloon plug, or pressure test balloon, expands to temporarily isolate pipes during repairs, or in the event of a spill. Pipe Balloon Plugs are available for isolating piping in line sizes from 1.5" through 66".

[bg_collapse view="button-red" color="#fff" icon="arrow" expand_text="Show More" collapse_text="Show Less" inline_css="width: 150px; padding: 10px;" ]

The innovative design allows the isolation plug to be smaller and more flexible which means it can be snaked through hot tap or branch pipes into larger pipelines that are otherwise inaccessible. Inflatable pipe plugs can inflate up to 8 times it's compact size to prevent the flow of liquids during maintance work or to block pipes or drains in the event of a spill (connects with your air compressor). The compact size also means that this plug takes up minimal storage.

While no isolation plug is one size fits all, USA Industries' inflatable pipe plugs conform to a wide range of line sizes and can inflate fully or partially to fit your application.

[/bg_collapse]

PRODUCT FEATURES:

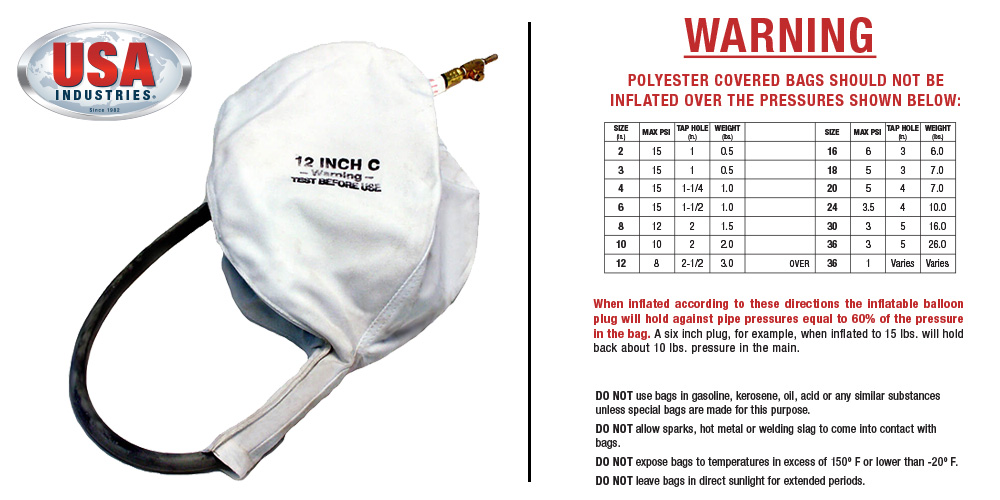

- Canvas outer shell with rubber bladder inside

- Expandable design conforms to a wide range of pipe diameters (I.D.); inflate partially or fully according to your application needs

- From the plugs compact or deflated state, it can inflate up to 8 times it's size to prevent the flow of liquids during repairs or to block pipes

- Ideally suited for short-term use

- When renting or purchasing, as an example, an 8" plug should be used on an 8" pipe

- NOTE: We do not recommend these be used for holding back-pressure*

*If holding backpressure is a requirement, ask us about our new and exclusive GripSafe® plugs, or one of our other low to high pressure rated high quality plugs

A SPECIAL WORD OF CAUTION: Pressure testing can be an extremely hazardous operation and safety precautions should be strictly adhered to. All connections, valves, flanges and other fittings should be checked for suitability to test pressure. Verify the line ID & Plug Range match. Most importantly - Never stand or pass in front of any test plug or other enclosure while test is in progress. If plug discharges during a test, serious injury or death could occur.

Frequently Asked Questions

Typically not on our canvas plugs, but we can provide a different style that does have vent through capabilities.

We have provided inflatable pipe plugs up to 66". If you need a larger size we can provide other solutions for you!

Yes, let us know what size hose you need.

Our inflatable pipe plug is available in heat resistent materials that can be safe for use up to 140°F.

Although they can hold a few pounds, we do not recommend these be used for holding back pressure unless it's for water and there would be a negligible impact if they failed.

The only thing that can be repaired is the valve stem inner fill stem.