Snap It® Jr. Mechanical Tube Plug

Snap It Jr. Tube Plugs - The Fastest, Safest, Most Cost-Effective and Reliable Way to Plug Tubes. Rated up to 1,000 PSID

USA Industries' Snap It® Jr. Mechanical Tube Plugs is the major engineering advancement you've been waiting for. Now you can install tube plugs without welding and in 80% less time, avoid tube sheet damage completely, and Snap It Jr is rated @ 1,000 PSID!

[bg_collapse view="button-red" color="#fff" icon="arrow" expand_text="Show More" collapse_text="Show Less" inline_css="width: 150px; padding: 10px;"]

Save Time & Labor Costs

The Snap It Jr Mechanical Tube Plug installs in just minutes. You do not need to remove the rear head cover because "through-the-tube plugging" can be performed. You can also skip the welding required for tube plugs in high-pressure applications, as Snap It tube plugs install in just minutes with a hydraulic ram and create a seal strong enough to hold up to 1,000 PSID. You can draw a direct line from saving time on installation to lowering your maintenance labor costs and reducing unit downtime.

Increased Safety

Blowouts from your Fin-Fan® / air cooled heat exchanger are extremely dangerous and, in the worst case scenario, can result in death. The Snap It Jr tube plug is verified to keep from blowing out at pressures that exceed 18,000 PSID. Also, because no welding is required to ensure a solid seal, you completely remove the risk of a spark igniting dangerous chemicals or fumes.

Extremely Cost-Effective

Snap It engineered tube plugs have a larger up-front cost, but customers will save in reduced labor and shortened unit downtime. This will result in significant savings after just the first use. Because most tube sheets must be replaced after repeated plugging with traditional methods involving welding or overdriving tapered pins, Snap It's unique installation process completely prevents damage to the tube sheets and tube sheet ligaments, which prevents costly maintenance downtime. When used to plug tubular reactors, it significantly decreases reloading times due to the plug's design and ability to not hinder the catalyst loading systems!

The Snap It Jr Mechanical Tube Plugs fit multiple tube sizes and are available in numerous materials. Tooling for installation and removal is fully compatible with any system, and we will rent or sell equipment to you inexpensively. USA Industries' is proud to guarantee a leak-free helium seal to 1 x 10-9 c/sec and will provide peace of mind that this plug will not fail!

Note: Always puncture the tube before installing any plug to ensure that pressure cannot build up in the tube and cause the plugs to loosen or blow out. Never stand in front of any installed plug under pressure. Plugs ejected under pressure can cause serious bodily injury. Blowout pressure testing was with standard-size tube plugs and in carbon steel and stainless steel.

[/bg_collapse]

Snap It Plugs should always be installed within the rolled section of the tubesheet. If the tubes are not rolled into the tubesheet, consult USA Industries (1-800-456-8721) before proceeding. Remove scale and pitting with USA Industries’ Snap It Brushes prior to installation. Any weld droop should be removed prior to plug installation.

SNAP IT JR PRODUCT FEATURES

- No tube sheet damage, no leaks, no worries!

- Blowout pressures exceed 18,000 PSID

- With NO welding required expect up to 80% in labor cost savings

- NO need to remove rear cover with through-the-tube plugging

- In-stock items ship within 24 hours

Find Your Snap It Jr Part #

Your Snap It Product #:

JR-4714915125245555846216496707127357748048378538999199629791024105410871103114911711212-

No products available for an O.D. this size.

Plugs in this size are available upon request.

Call Us Today!

Your Snap it Accessories:

Pull Rod Assembly:

PRA-

Channel Head Pull Rod:

CHPRA-

Brush Kit:

JRA-

Plug Positioner:

PP-

[sc name="snap-it-jr-specs-accessories"]

USA Industries Snap It® Plug, Tools & Accessories Training Series

1 – Introducing USA Industries Snap It® Plug Installation & Removal Tools Kit

2 – Assembling Tools Contained in USA Industries Snap It® Plug Installation & Removal Kit

3 – Brushing & Piercing Heat Exchanger Tube Using USA Industries Snap It® Tools

4 – Near End Installation of USA Industries Snap It® Jr. Plug in Heat Exchanger

5 – Removal of USA Industries Snap It® Jr. Plug from Tube

6 – Through-The-Tube or Far End Plugging of USA Industries Snap It® Jr. Plug

Frequently Asked Questions

Snap It Jr. tube plugs are rated @ 1,000 lbs of pressure, but with our independent testing, we've seen blowout pressures exceeding 18,000 PSID.

We can make your Snap Its in any exotic or standard metal, and regularly produce tube plugs in more than 20 different materials. Most commonly requested metals include: 70/30 CuNi, 90/10 CuNi, Brass, Carbon Steel, Chrome/Moly, Hastelloy, Inconel, Monel, Nickel 200, Stainless Steel (316 and 304), Titanium, Zirconium and more.

We sell our Snap It plugs in sleeves of 10. There is no maximum. We have the capabilities to produce 5,000 plugs daily, and have more than 500,000 tube plugs of all varieties in stock at all times. Even custom orders, can typically be manufactured and shipped extremely quickly!

Snap It Jr. tube plugs don't require welding, completely removing the risk of a spark igniting dangerous fumes or chemicals.

With Snap It, you can guarantee a consistent and controlled installation, making the entire process safer and more predictable. With proper installation, Snap It Jr. tube plugs have an average safety factor exceeding 18.

We strongly suggest never standing in front of an installed tube plug of any type.

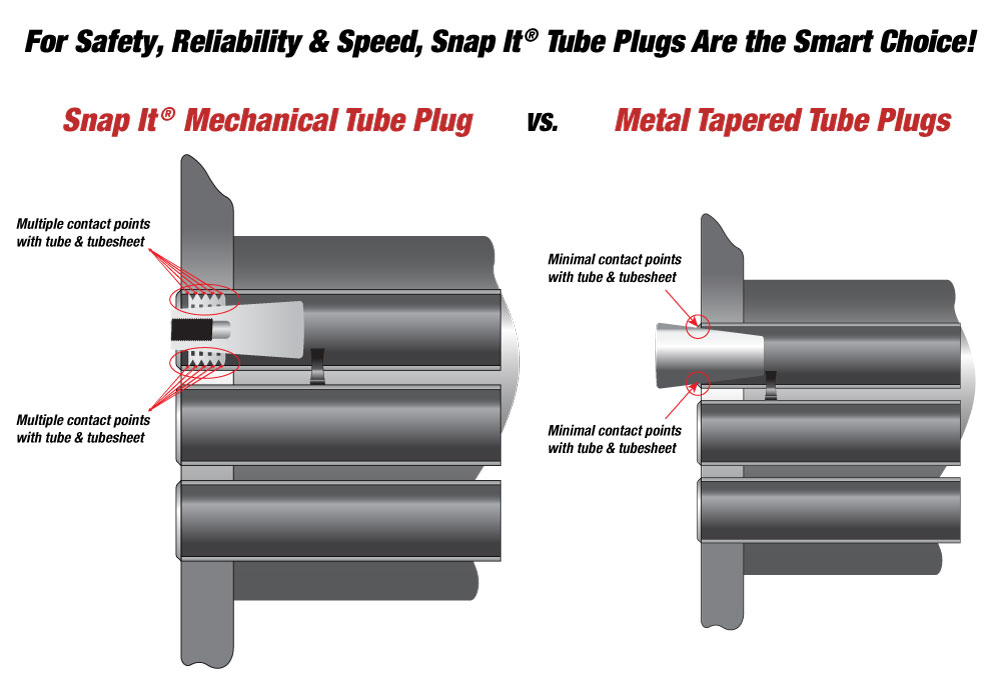

Snap It Jr. tube plugs are rated @ 1,000 PSID and have three points of contact. They also cover a wider range of Tube I.D.s.

Our Snap It Sr. tube plugs are rated @ 7,000 PSID and have five points of contact, but they cover a more limited range of I.D.s.

The Jr. Plug is suitable for most applications. The Sr. Plugs are used most commonly in high-pressure applications.

Both Snap It Sr. and Snap It Jr. tube plugs require some tools for installation and removal. We strongly suggest using tube brushes to clean and prep your tubes, then installation is a breeze. Our hydraulic ram and pull rod assemblies provide consistent, controlled intallation, eliminating the hazards of tapered and welded plugs, as well as tube and tube sheet damage.

Once you've installed a few Snap Its, you'll find it takes less than 60 seconds to prep and install these tube plugs. Now you can skip welding, and save up to 80% in labor costs with a quick and consistent installation process!

Our Snap It Tube Plugs require ZERO proprietary pieces of equipment to install. Don't get locked into expensive equipment issues after your purchase. Call us and we can confirm your existing tools will work with ours. If not we offer short-term rental and purchase for installation tooling.

Yes, we sell directly to end-users, as well as other contractors and suppliers.

We design, engineer, manufacture, test, and package Snap It Plugs at our facility in South Houston, Texas, and we ship anywhere in the world. As the manufacturer, we are uniquely qualified to provide technical support, certification training, and customizations to meet your specific needs.

Our customers experience competitive pricing and short lead times by dealing directly with USA Industries, Inc.

Yes, Snap It Jr. Tube Plugs are regularly used for both near-end and far-end applications.